Load rate and load force

Load rate and load force

When we choose the type of cylinder, we need to calculate the “load force” according to the designed mechanism and workpiece. Before calculating the load force, let’s talk about the concept of load rate.

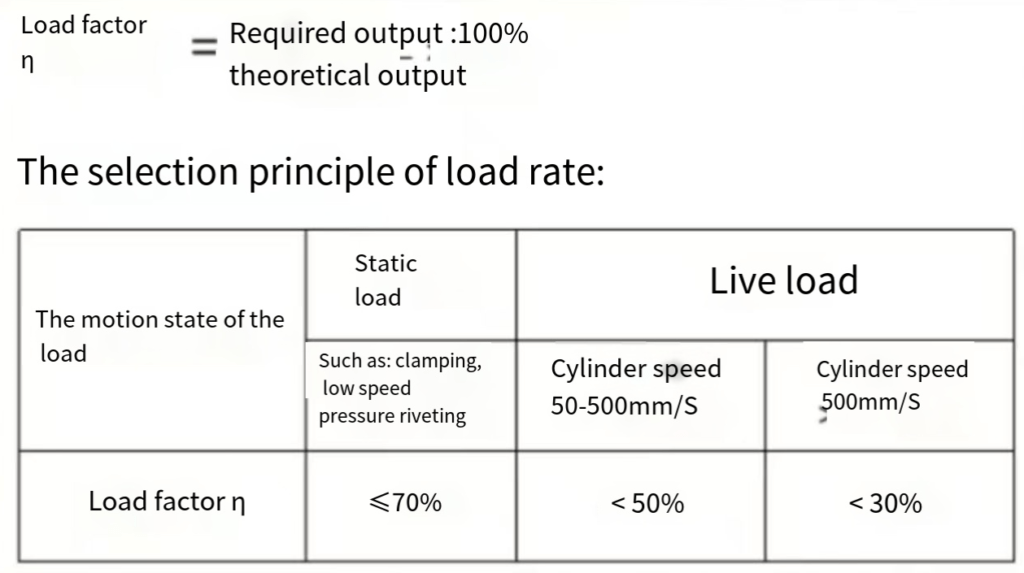

- Load rate: refers to the ratio of the axial load force (required output) F of the cylinder piston rod to the theoretical output force F0 of the cylinder.

(Note: According to the direction of the required output, the theoretical output FO = F1 or FO = F2),

- Load force: refers to the axial force F on the cylinder piston rod, and it will choose F = F1 or F = F2 according to different usage conditions.

Second, the cylinder selection calculation steps

Step one

We first select “load rate n” according to the “selection principle of load rate” according to the motion state of the load (no need to consider the angle problem)

Step two

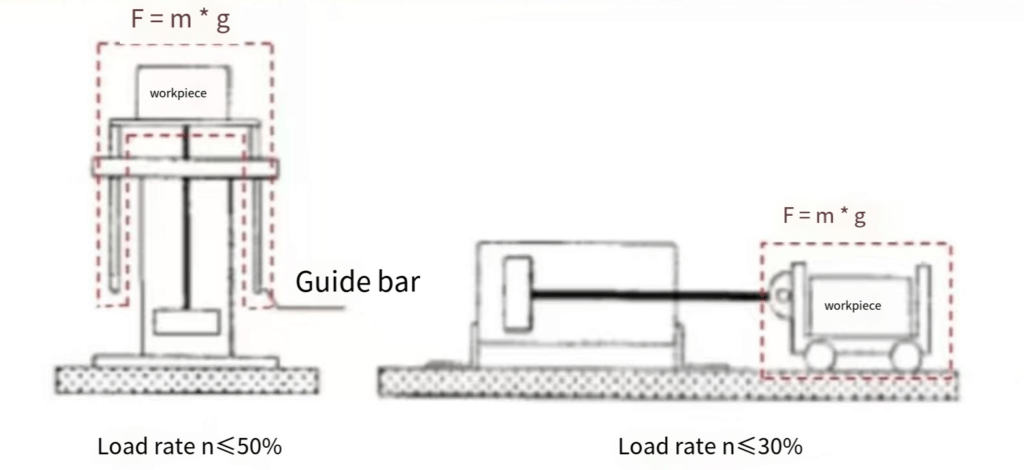

Calculate “Required Output”: Determine the relevant load weight: the load force generated by the movable parts of the workpiece, fixture, guide rod, etc.

How to calculate the “required output”?

(1) According to the figure below, calculate the load force F (weight m (KG), g = 9.8N/KG), for the inclined cylinder, the load rate can be selected as 40%.

Web: https://vpneumatic.com

Tex/Fax:0086-577-62840011

WhatsApp:0086-13355775769